Printed Electronics for 6G Smart Surfaces Everywhere, IDTechEx Explores

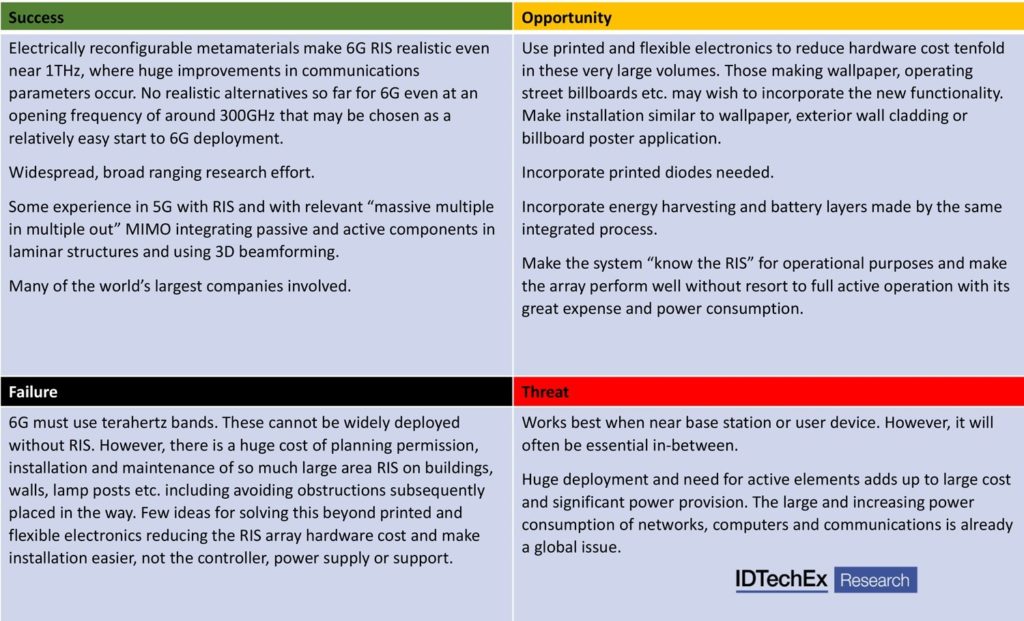

6G Communications is coming to your smartphone around 2030, according to Samsung and others. It can only succeed with its holographs, instant downloads and other goodies if it deploys smart surfaces everywhere. From ceilings to billboards and building facades, they must enhance and redirect the far-infrared “terahertz” beams needed because such emissions are feeble and subject to weather and things in the way. The only report that sizes and scopes this aspect is IDTechEx, “6G Communications Reconfigurable Intelligent Surfaces Roadmap, Materials, Market 2021-2045“.

Essential is printed electronics, with line widths of only a few microns eventually, when the second stage 6G operating frequency reaches one terahertz level. 6G will likely start at 0.3THz or so, meaning easier line widths and larger feature sizes at one-tenth of wavelength. Initially, only conventional semiconductor components will be placed behind the printed metamaterial patterns, preferably printed in copper at one-tenth of silver material cost. Printing semiconductor devices comes later. Research is early stage and it currently ignores cost issues despite their vital contribution to the viability of the whole 6G project. In a casual mention, some researchers say flexography or photo-etching may have a place.

IDTechEx is the leading market and technology expert in printed electronics. Its multi-lingual PhD level analysts are deployed worldwide. They calculate that this new printed electronics opportunity can hit over $7.5 billion by 2034, necessitating a considerable scale-up of current electronics printing facilities.

In the report, some of the thin-film technologies appraised for the application are electrohydrodynamic, flexography, flexoprint and plate, photoresist, photolithography with etching, photocurable screen printing and embossed fine metal patterning. The achievements of the leading proponents are appraised and compared.

Raghu Das, CEO of IDTechEx advises, “This is not just a matter of cost reduction, though printed and flexible electronics will be essential to make the envisaged vast areas viable. There are other issues such as self-powering and easy integration into wallpaper and billboards without compromising performance. Maximum benefits are planned at the second stage of 6G, including amplifying the beam before redirecting it, operating unpowered internet of things nodes and even charging your smartphone from the beam. The new high electron mobility transistors HEMT and other components added must be made thinner and over-printed with metasurface patterning and much higher power must be produced and handled on film to achieve that endpoint.”

IDTechEx finds that the basic Reconfigurable Intelligent Surface RIS will consist of PIN diode-biassed so-called “semi-passive metasurfaces” at around one dollar per square meter at the likely global demand by area that it forecasts. However, the devil is in the detail. You need to add power supply, phase shifters and controller even to the ultra-low-power launch product of 1-100 square meters.

This power can come from a printed photovoltaic layer. The RIS will need protection layers costing more and overlayers must be transparent to the emissions and, ideally, self-cleaning. THz-transparent adhesion layer for a smart poster? Most of these additional issues will be solved with printed and thin-film electronics produced reel-to-reel.

IDTechEx finds that 6G cannot happen without RIS, and RIS cannot happen without printed metasurface arrays and allied patterning. Governments and giant companies invested one billion dollars in 6G research in 2020 because they see the trillion-dollar opportunity driving strength of nations and even being a national security issue. However, just recently, those involved are starting to note that the glamorous machine learning and artificial intelligence mathematics are well served but what they see as the more-prosaic but essential reprogrammable intelligent surfaces are relatively ignored. It is not even known if the various printed semiconductors and dielectrics should employ 3-5 compounds, vanadium oxide, liquid crystal polymers, or other options examined in the report.

So, “In a gold rush, get there first and sell shovels”? Not really. It is now realized that 6G is as much a hardware challenge as a software and systems one. The 6G systems people may dismiss RIS as an easy, secondary matter, but RIS need the most sophisticated skills of experts and many unsolved issues must be solved within the allotted timescale. That could lead to a great deal of high-added-value printing business and associated demand for advanced materials, some of them new.

For more information on this report, please visit www.IDTechEx.com/6GRIS or for the full portfolio of research available from IDTechEx please visit www.IDTechEx.com/Research.

SOURCE IDTechEx